Information

Prints form files

If you already have your own STL file, simply select the material and color to receive an quick response.

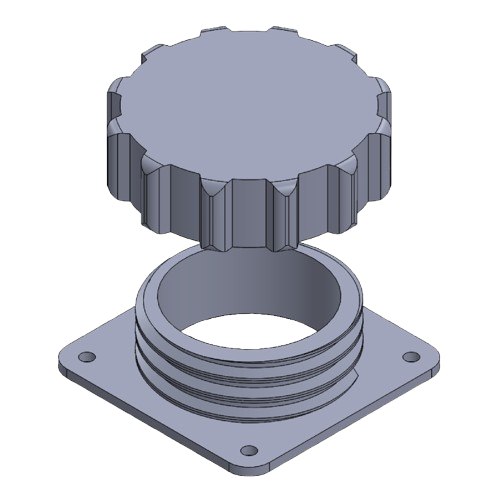

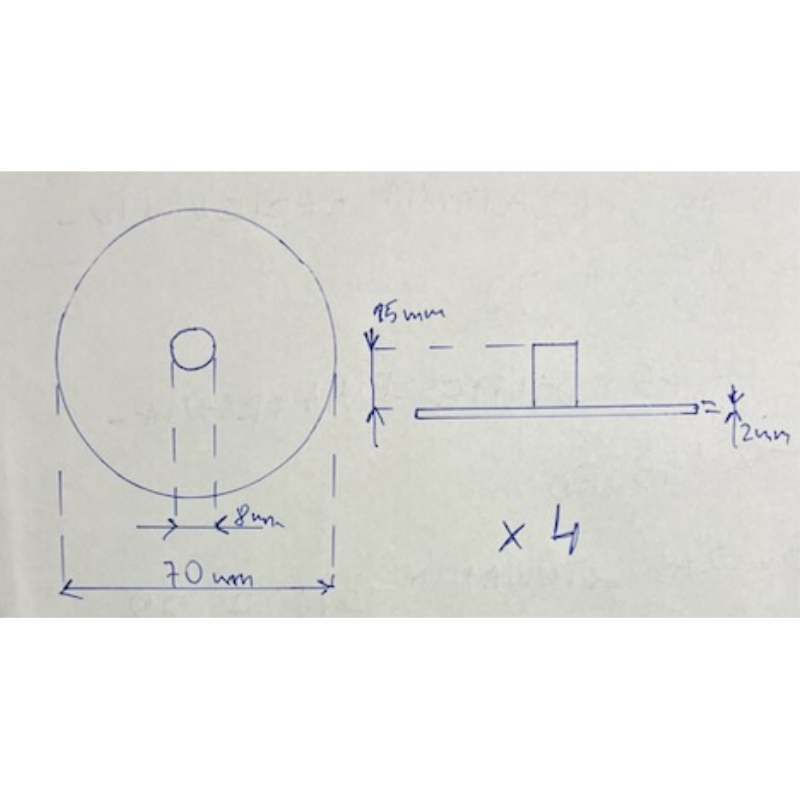

Prints from drawings

If you don’t have a file but only a drawing of your print, use the contact form to receive a free quote within 1 day.

Projects

They usually require consultation and possible minor adjustments to adapt to the printing process. Please contact us using the form.

Available materials

their colors

example usage

PLA

Eco-friendly, it features good stiffness and aesthetics but has low resistance to high temperatures and impacts. Ideal for decorations and prototypes. Prints made with PLA will have the best look .

PETG

More durable than PLA, resistant to moisture and temperature. Perfect for technical components. It technically replaced once very popular ABS (due to its much lower toxicity to the environment).

FLEX

Also known as TPU, a flexible, bendable, and durable filament. It allows for the creation of hard rubber elements, such as gaskets, protectors, or damping parts. The hardness of printed objects on the Shore scale is 95A.

3D Printing

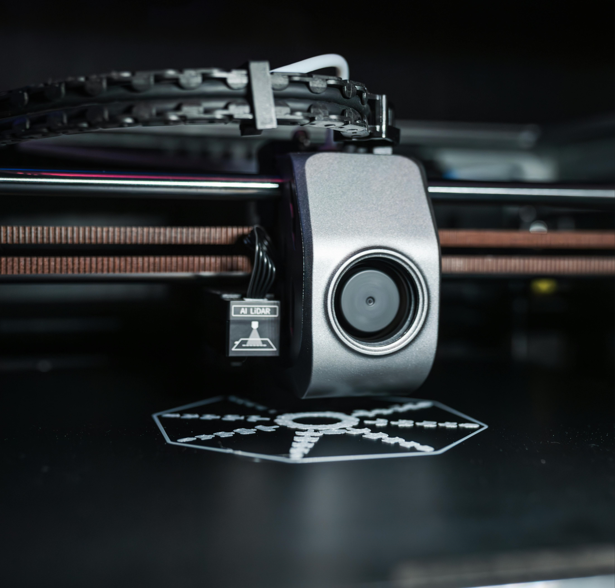

FDM

Printers specifications

Filament 3D printing

3D printing using FDM (Fused Deposition Modeling) technology involves melting plastic material (filament) and depositing it layer by layer to create a three-dimensional object.

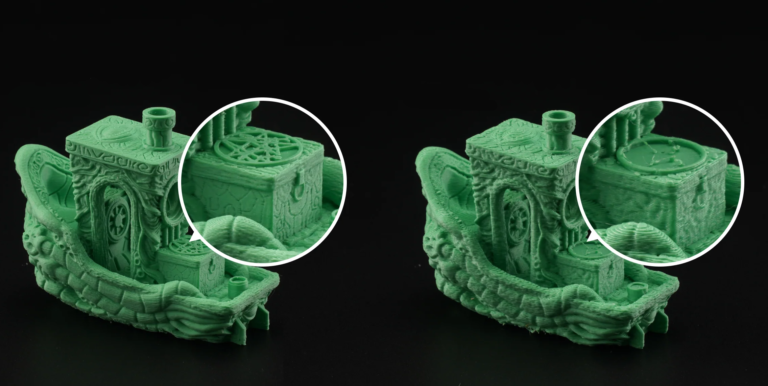

Nozzle

The nozzle is the part of the printer through which the melted filament is extruded. The nozzle diameter affects the precision and speed of printing:

0.2 mm nozzle: Offers higher precision but prints slower, and the objects are less durable. Ideal for small, detailed models.

0.4 mm nozzle: The most popular size. Combines good precision with speed and print durability. Ideal for most projects.

In the example comparison, the boat is only 3 cm tall.

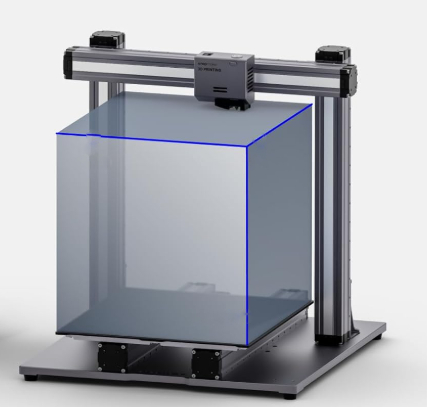

Build area

The build area is the space where the printer creates an object. Special build surfaces (e.g., PEI foam, glass, or construction tape) are often used to improve adhesion. For my currently available printers, it is 25x25x25 [cm].

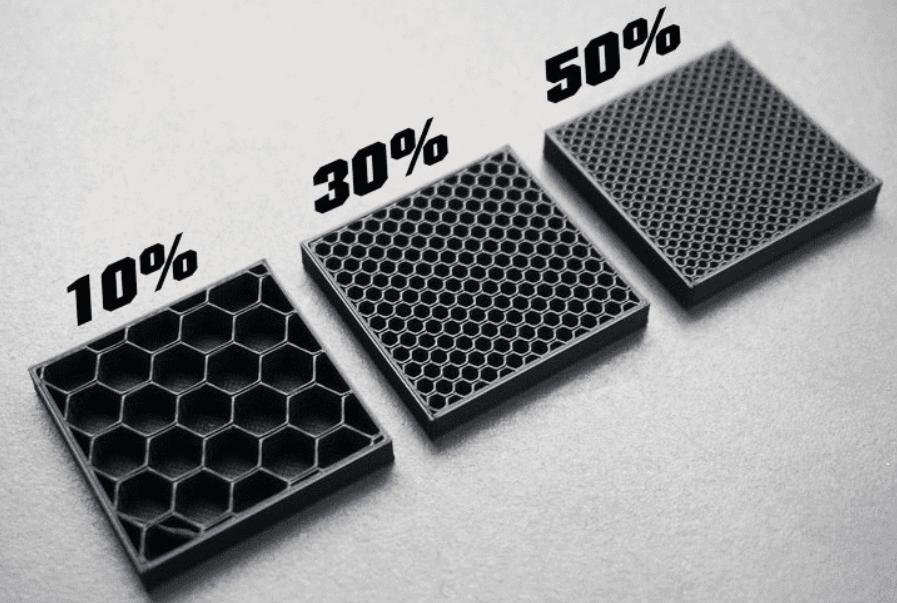

Infill

Infill is the internal structure of a printed object. It is specified in percentages:

Low infill (10-20%): Lightweight and economical printing, suitable for decorative models.

Medium infill (30-50%): A good compromise between strength and material usage.

High infill (70-90%): Very durable models but consume more filament, increasing printing costs and the weight of the object.

90-100% infill is unavailable due to the thermal expansion of the filament – such prints are almost never successful and also have lower strength than 90%.

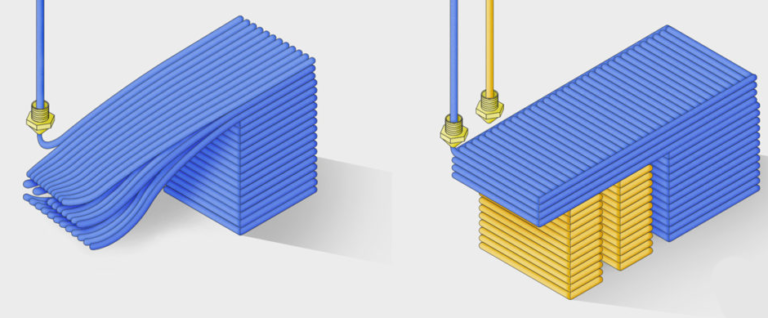

Supports

Supports are temporary structures printed along with the model to support overhanging elements or complex shapes. They are removed after printing is complete. They are necessary when the model has elements protruding at an angle greater than 45 degrees.

Highlighted in yellow in the preview image.

Libraries of

STL models

to 3d print from

Thingiverse

The largest library of free 3D printing files.

Thangs

Paid version of Thingiverse.

Etsy

The largest store for digital items, including STL files.

Printables

Alternative to Thingiverse.